Kerex invests in qualityy

Kerex belongs to the leading European manufacturers of swap bodies for trucks, transport systems for combined transport, technology containers, as well as manufacturers of other products for European customers.. In order to get the quality of its products, especially quality finishes to the highest level, the company has invested great resources into a new technological line with cathodic dip coating (KTL) a subsequent powder coating. The introduction of this technology will help our products to reach the quality of surface treatment and especially the level of corrosion protection that it was previously seen only in the automotive industry.

Cathodic Dip Coating - KTL

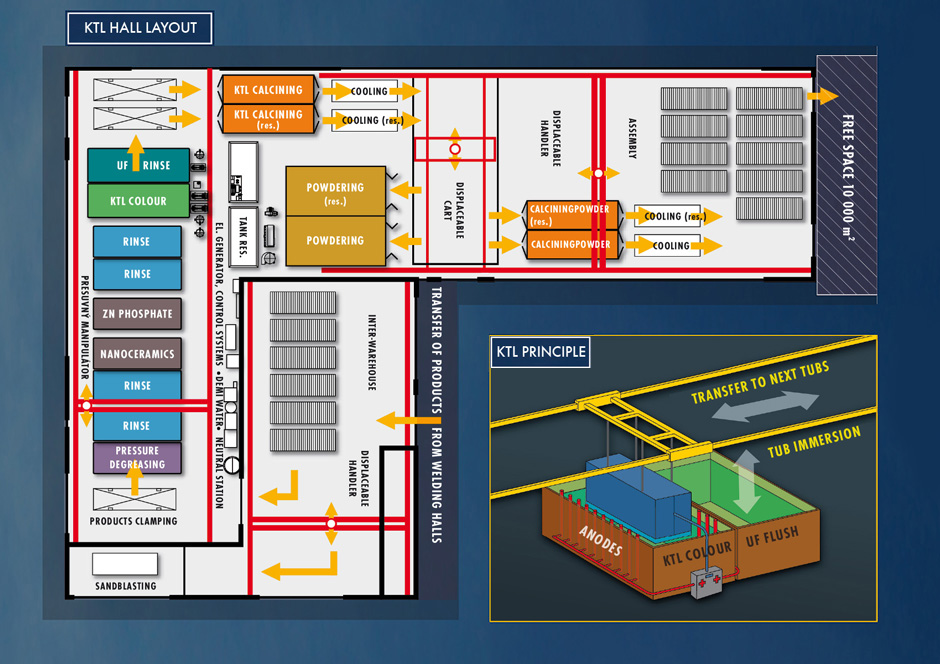

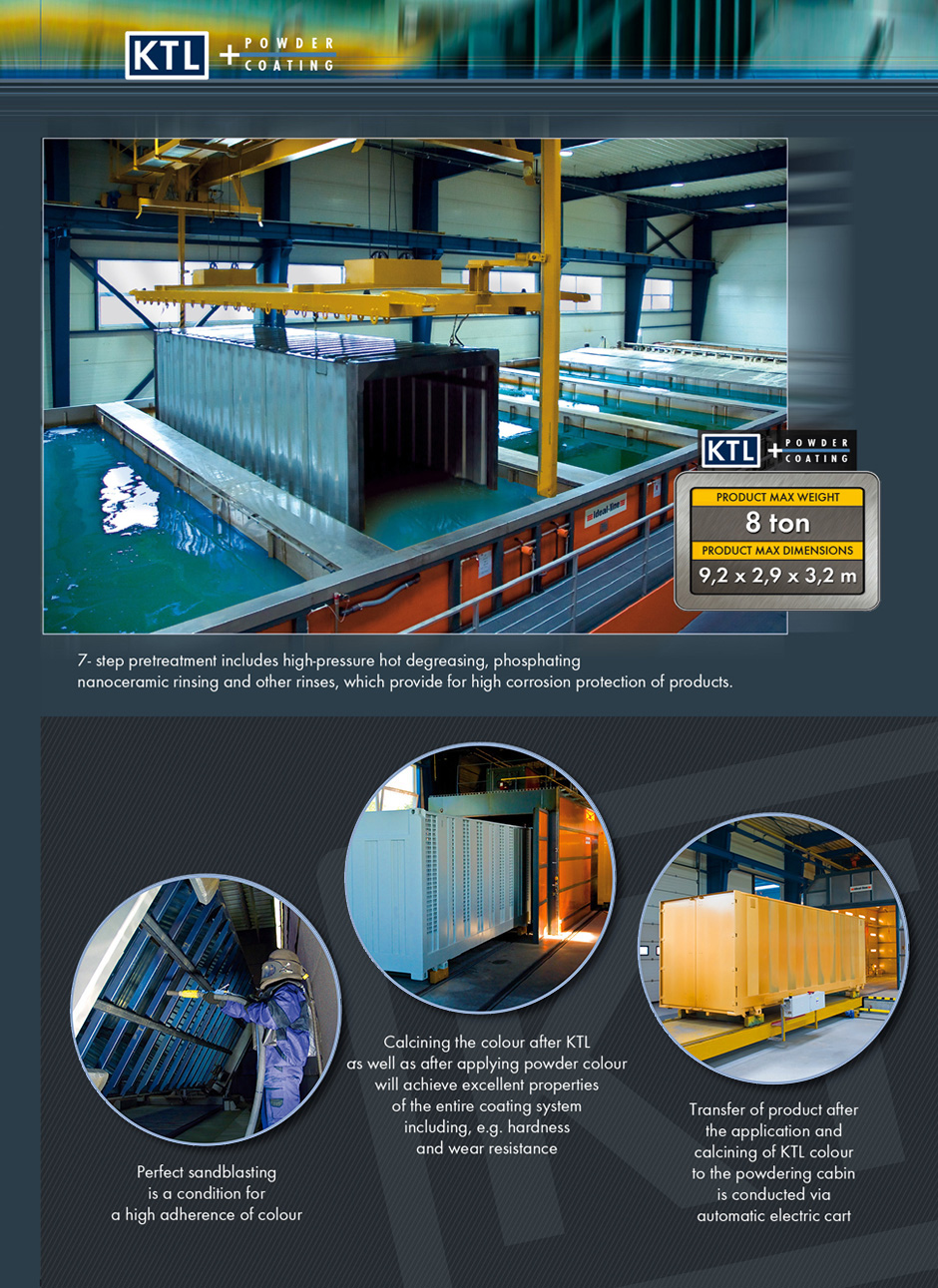

Cathodic dip coating is the perfect combination of corrosion protection, productivity, economy of production, surface quality, and the protection of the environment. KTL provides the products of Kerex with a for a long-term corrosion protection, high resistance to mechanical damage and resistance to salt water and chemicals. During the KTL, the product is completely immersed in a KTL tub with a liquid colour, which is immersed and placed on sides and bottom of the KTL by the use of anodes and recharged with the positive pole. The immersed product is during this process connected to the negative pole and acts as the cathode.

This procedure facilitates the electrolytic process, which provides for a uniform thickness of colour over the entire, even rugged, surface of the product. The colour gets into all cavities, corners and edges. After removing the product from the KTL tub, it is immersed into another tub, where it is rinsed from paint residues, which have not been clamped to it electrostatically. This results in a completely smooth surface. Next step is the calcining of the product in an over at 180oC. Technology: KTL is used as a final coat or as a primer under powder coating, which is applied to all Kerex products together with an initial sandblasting of products, providing for the highest quality of surface treatment, which is available today on the market.

Powder Coating Application

Kerex applies powder coating on sandblasted and KTL-primed surface. Powder coating provides for an excellent optical properties of the coating and UV resistance and serves as a perfect barrier against moisture. Powder coating means solid particles without the use of diluents and hardeners. The application is done by the use of handguns or automatic equipment. Applied powder is attached to the product by means of electric charge. Thus coated product goes into the calcining oven, where the product is polymerised at approx. 160 - 200 oC and spills over the surface, which creates a perfectly smooth surface.

Technology Applicability

- Steel, sheet steel

- Cast iron

- Galvanized steel, galvanized sheets

- Aluminium

Advantages

Advanced technology consists of a perfect sandblasting of a surface, KTL - coating and powder coating. This provides all Kerex products with the following properties:

- Longitudinal long-term corrosion protection corresponding to the salt spray tests according to the standard DIN EN ISO 9227

- Perfect mitigation of undercutting e.g. in case of mechanical damage on the surface

- Excellent resistance to chemicals and oils

- Even layer of paint with small thickness colour tolerance

- High optical properties of the coating

- No formation of colour drops and spills

- High UV stability

- Very good coverage of holes and corners

- Perfect coverage of edges and welds

- Minimal discolouration during application

- Suitability for rugged products with different geometry

- Environmentally friendly thanks to the use of KTL - water based colours, therefore without the use of conventional diluents

Typical Applications

- Automotive parts

- Agricultural machinery

- Parts of trucks, e.g. body, axles, frames, brackets, gear

- Construction machines, e.g. cockpits